Why is initial cooling of Cryogenic tanks required prior to loading ?

Preparation for loading flammable gases in ISO Cryogenic tank containers needs extreme caution.

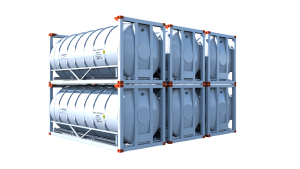

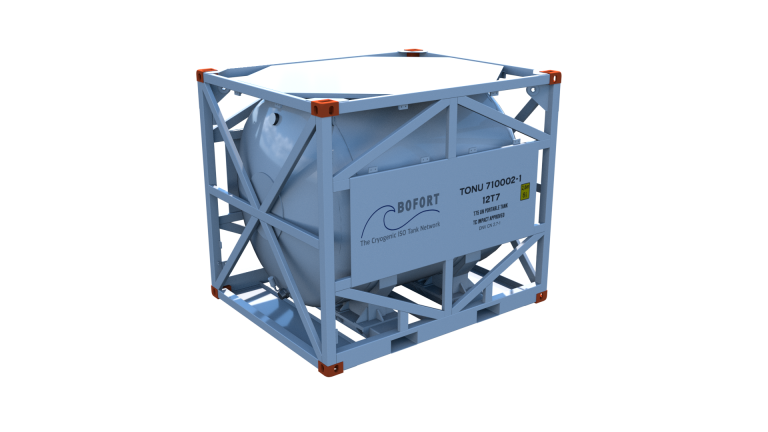

ISO Cryogenic tank containers are designed to withstand a certain service temperature; if this is below ambient temperature the system has to be cooled down to the temperature of the load before transfer. For LNG and ethylene the stress and thermal shock caused by an over-rapid cooldown of the system could cause brittle fracture. Bofort ensures that cooldown operations are carried out carefully in accordance with manufacturers instructions and with expertise.

Initial cool down of ISO Cryogenic tank containers

Initial cool down of ISO Cryogenic tank containers

Cool down is an operation to pre-cooling cryogenic tank containers and lines required before taking on cryogenic flammable gasses. ISO Cryogenic tank container cool down is carried out by spraying nitrogen through the spray nozzles of each tank. The cool down operation from an ambient temperature to a planned temperature, is called ‘initial cool down’ and is to be differentiated from an ordinary cool down operation carried out during transit.

Before a flammable gas can be introduced into a Cryogenic tank containers, the tanks have to be cooled down to a temperature close to that of the gas which is to be loaded. The reasons for this are as follows:

1. Vapor generation

1. Vapor generation

If a cryogenic gas is introduced directly into warm tanks, the cryogenic gas will almost immediately turn into vapour. LNG for example has a liquid to gas expansion ratio 1: 600. Therefore, to enable the liquid to be loaded into the tank at a reasonable loading rate, the necessity of large compressors are required to remove the vapour generated in the process.

By reducing the cargo tank temperature, the amount of heat that is available to transfer into and heat the LNG is minimized. Consequently the amount of vapour generated can be maintained within reasonable limits.

2. Cargo tank material

Bofort’s ISO Cryogenic tank containers are constructed of stainless steel which retains its flexibility and strength characteristics over the temperature range being considered (-196ºC +50ºC). However problems could occur if the material is subjected to very local and rapid cooling such as when a small droplet of cryogenic gas comes into contact with a warm tank wall. Because of the transfer of the heat from the wall into the liquid, the temperature at the particular point will decrease rapidly causing large thermal stresses to arise between the point and the surrounding material. This could lead to stress cracking. (cold spot)

3. Pipe work construction

3. Pipe work construction

The pipe-work with the tank is constructed of stainless steel tubes. If subjected to rapid cooling thermal stress within the material can be excessive, leading to the material cracking.

All three reasons are of equal importance as each, if not carefully controlled, can have a significant impact on the tank structure and overall safety of the tank.

ISO Cryogenic tank containers cool down with LIQUID NITROGEN

After the cargo system has been gased up the headers and tanks must be cooled down before loading can commence.The rate of cool down is limited for the following reasons.

To avoid excessive stresses. vapour generated during the cool down of the tank must remain within the capabilities of the compressors, to maintain a tank pressure safely below of the release pressure of the safety valves.

Nitrogen is supplied from the terminal or other supply to the cool down line and from there directly to the spray header. The various spray valves are operated in order to produce a temperature profile in line with, but not exceeding, the manufacturers’ instructions. Some tanks may require a minimum temperature before bulk loading may commence; this temperature is to be strictly adhered to.